HOME > DRY ICE BLASTING > EXPLANATION

Explanation of the Dry Ice blasting Process

Dry ice cleaning: how does it work? The cryogenic cleaning technique represents a tremendous advance concerning industrial cleanliness. However, it remains a mystery to many neophytes, and perhaps you are one of them. Discover the explanations of dry ice blasting in this article and video.

Dry ice cleaning in a few words…

Cryogenic cleaning is a cleanliness technique that uses dry ice and its physical properties as a means of an instantaneous detachment of pollution or dirt.

Dry ice (solid carbon dioxide) has the hardness of chalk, so this process gently cleans surfaces. To discover all the advantages of this industrial cleaning technology, click on the link at the bottom of the page, advantages of dry ice cleaning.

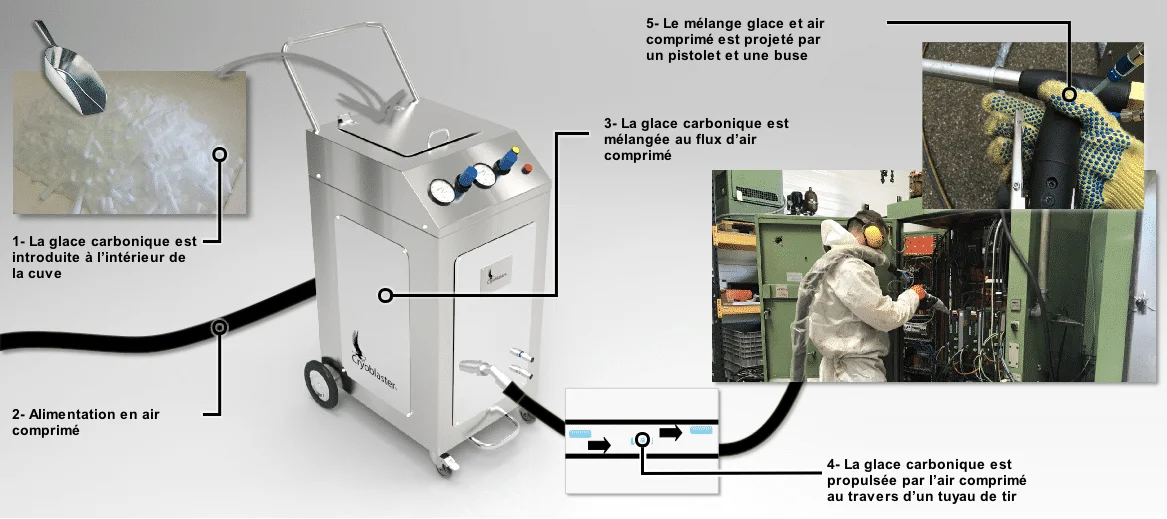

The Cryoblaster® process uses the projection of dry ice through blasters and compressed air. See illustration below.

Dry ice blasting explanations (video)…

Dry ice in the form of 3 mm pellets is introduced into the blaster inside the tank or hopper (1).

After connecting the compressed air supply (compressor or factory pressurized air network) (2) and starting the cryogenic cleaning unit, the dry ice is mixed with the compressed airflow inside the blaster (3), and then propelled to the work of a firing hose (4).

Finally, dry ice is projected onto the surfaces to be cleaned using a gun from a supersonic speed spray nozzle (5).

Dry ice cleaning is based on the simultaneous action of 3 physical phenomena

See video below

1- Kinetic energy

Dry ice in the format of pellets with a diameter of 3 mm is projected at very high speed on the surfaces to be treated thanks to compressed air and the use of supersonic nozzles (convergence/divergence).

Dry ice is thus charged with kinetic energy(Ec= 1/2mV²).

During impact, the pellets generate a localized shock wave that facilitates the de-cohesion of the pollution on the treated surface.

However,it is important to remember that the energy transfer to the support is minimal, for 2 reasons:

– First: the hardness of dry ice is comparable to that of chalk. Less dense, less heavy, dry ice is non-abrasive.

– Second: the almost instantaneous transition (or thousandths of a second) from the solid-state to the gaseous state of dry ice, therefore, allows only a minimal transfer of energy, as indicated above.

2- Thermal differential

The temperature of dry ice pellets is very low at -78.5 °C and gives the cryogenic cleaning process undeniable thermodynamic properties!

Depending on the type of pollution or contaminant being treated, the temperature difference between the dry ice and the support, or thermal shock, can occur. As the temperature of a contaminant or pollution decreases, it becomes brittle, allowing the impact of pellets to break up the pollutant.

The thermal gradient or difference between two different materials with different coefficients of thermal expansion can also facilitate the debonding of the pollutant from the support. This thermal shock or thermal differential is more evident when cleaning by cryogenics a non-metallic coating (e.g. electrical cabinets covered with dry residues) or a contaminant linked to a metal substrate (e.g. die coating on foundry mold)

The hotter the temperature of the surface to be treated, the faster and more economical the cryogenic cleaning process is (e.g. aluminium foundry gravity mold).

Many companies are interested in the cryogenic cleaning process, but are concerned about the reaction of their tools to the cold of dry ice: studies have shown that the drop in temperature occurs only on the surface, so there is no risk of heat stress in the metal mass of the support. Ex: plastics molds.

3- Sublimation

On impact, dry ice sublimates (transition from the solid-state to the gaseous state) in a ratio of 1 to 700. We can talk about micro-explosions.

The dirt is literally blown out. All that remains is to suck up the dirt or residue. The treatment is dry and does not generate secondary waste, unlike the use of a pressure washer or a sandblaster.

Other articles on the same topic

Cryogenic cleaning: principle of action

Discover additional information on the mechanism of dry ice cleaning, in High Definition video.

Address

Delta Broadcast

Head office

Rue Du Bonnard

38290 Frontonas (France)

SHOWROOM ADDRESS

Showroom

Rue Des Muguets

Parking Carrefour Market

38070 Saint Quentin Fallavier

WEB ACCOMMODATION

Ovh

2 Kellermann Street

BP 80157

CEDEX ROUBAIX 1

Phone : +33 8 99 70 17 61

CONTACT

Tel: +33 981 37 76 93

Website: www.cryoblaster.com

Email:

contact [at] cryoblaster.fr