Dry ice blasting machines

Discover the electro-pneumatic dry ice cleaning machines (ATX nano, ATX25-E) or 100% Pneumatic (ATX25-P) by clicking on the link below.

Dry ice blasting : at the service of your surfaces and your activity

Cryoblaster® is a range of “dry ice cleaners” or dry ice blasting machines, adapted to the rehabilitation of surfaces and which benefits from the latest technological advances:

– Nanotechnological insulation, high-frequency vibrator, optional abrasive kit, supersonic nozzles very high aggressiveness (special heavy work)…

The Cryoblaster® range has been specially designed for surface treatment operations: cleaning, stripping and preventive or curative industrial maintenance.

Cryoblaster® equipment is used every day in the following industries: plastics, foundry, food processing, pharmaceutical industry, aeronautics, electricity…

Only the best components on the market equip your Cryoblaster®: Festo®, Siemens®, Phoenix Contact®…

NEWS

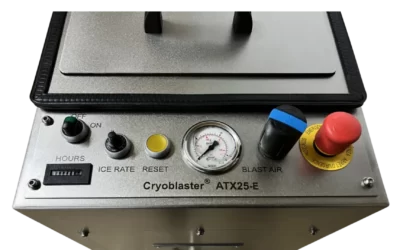

ATX25-E V1 Dry Ice Cleaner

HOME > EQUIPMENT: DRY ICE BLASTERS > ATX25-E V1[dsm_perspective_image src="https://cryoblaster.com/xeftossu/2022/09/machine-nettoyage-cryogenique-atx25-E-v1-862-1150.webp" title_text="machine-nettoyage-cryogenique-atx25-E-v1-862-1150"...

ATX Nano Pneumatic: new blaster

HOME > EQUIPMENT: DRY ICE BLASTERS > ATX nano-PATX nano...

New universal dry ice blaster

HOME > NEWS > UNIVERSAL DRY ICE CLEANERNew MACH3: universal dry ice cleanerDiscover the new MACH3, a dry ice blasting machine universal, that allows you to work with all dry ice formats on the market! This article is taken from the News section.Universal dry ice...

Dry ice cleaning today:

The world has evolved and with it its share of advances and techniques, leading to the appearance of contaminants of a new kind.

Current industrial cleaning techniques are not necessarily the ones that give the best result.

To try to remove contaminants, products are very frequently used that for a large majority of the latter, solvents, detergents, sometimes give poor results and involve the treatment of secondary waste. Examples: cloths soiled with pollutant, abrasive mixed with contaminant…

There is, however, a technology that is truly beneficial to the environment, in terms of profit and more importantly in terms of efficiency.

What is this technology called? The cryogenic cleaning process.

Dry ice cleaning: explanations of the process, steps…

The cryogenic cleaning technique uses dry ice or dry ice (– 78.5 °C) as a cleaning agent.

The format used is pellet with a diameter of 3 mm (in the shape of sticks), and in the vast majority of cases the ice used is food grade.

You can get this precious media from gas companies such as Air Liquide, Messer, Air Products, Yara… or with one of their partners.

How does it work? Dry ice is placed inside the hopper or tank of a blaster.

This is then mixed with the compressed air using a rotor plate : by rotating the plate, the solid CO₂ pellets are faced with a compressed airflow. The resulting mixture is then conveyed through a firing pipe.

The projection of the ice on the surface to be cleaned is carried out using a gun and a spray nozzle.

The source of the compressed air may be either:

– an industrial network,

– a network of workshops,

– an electric or thermal construction compressor

The interest in cleaning by cryonics lies in the triple action of dry ice, which makes it a real solution to the removal of new contaminants.

By clicking on this link to know everything about dry ice cleaning,

you will discover a wealth of information on this process!

The first step is the mechanical shock or mechanical effect caused by the dry ice, projected at high speed or high velocity on the pollution: dry ice creates cracks on the contaminant (varnish, paint, glue …).

This leads to a weakening of pollution. This is made possible thanks to the kinetic energy stored by the pellets during their spraying (pellets are accelerated): Ec= 1/2 m (weight of CO₂) x V² (projection speed)

The second step is the thermal shock or thermal effect, also called “thermal differential”. Dry ice at -78.5 °C cools the pollution. This difference in the temperature of the pollution and the support retracts the latter without damaging the surface or substrate.

The third step is sublimation or change of state: the passage from the solid-state to the gaseous state of solid CO₂ into GAS CO₂, in a ratio of 1 to 700. The dirt is removed by the breath!

Cleanliness operation by spraying dry ice. Purpose of the treatment: hydraulic unit

Dry ice blasting: an ecological treatment that does not involve the reprocessing of secondary waste

Ice blast cleaning is truly an ecological cleaning technique because unlike the use of sandblasting, aero scrub, hydroscrub or high-pressure cleaning, it does not generate secondary waste to be reprocessed.

The dry ice cleaning technique causes the removed dirt to fall by gravity. As a rule, a sweep or the use of vacuum cleaners (or suction) is enough!

The costs of reprocessing disappear.

Cryogenic cleaning is professional cleaning to the greatest degree!

For the degreasing of your surfaces (substrates), or to remove all types of dirt: ink, varnish, glue … or to remove food residues, this process is ideal!

Without chemicals, and without cleaning products, to ensure exemplary cleanliness of your production processes, the Cryogenic cleaning equipment Cryoblaster®, allows thanks to the projection of dry ice pellets (carbon dioxide), the dry cleaning of the surfaces to be treated: no oxidation possible, dry ice does not contain water.

Carbon dioxide in solid form (compacted dry ice) is an excellent low-temperature degreaser.

For cleaning in the food industry, or for interventions or decontamination after a fire damage, or for the treatment of surfaces with non-abrasive CO₂ pellets or balls, Cryoblaster cryogenic cleaning machines® are the essential tools for service providers and manufacturers.

All the advantages of dry ice blasting: dry, non-abrasive, economical process:

- Cryogenic cleaning is a dry process. Because solid CO₂ does not have traces of moisture, you may want to consider cleaning a power-off electrical cabinet or dry cleaning after a fire.

- Cryogenic cleaning is non-abrasive unlike sandblasting or aeroscrub because the hardness of solid CO₂ is comparable to that of chalk; it is, therefore, respectful of the treated surfaces.

- Cryogenic cleaning is much faster than traditional cleaning methods: at least 4 times and up to 8 times. It requires little or no disassembly.

- Unlike sandblasting or the use of a Karcher the service can be carried out In the original location: no water, no sand …

- The use of cryogenic cleaning in an agri-food environment slows down the proliferation of the following bacteria:

E.Coli, Listeria Monocytogens, and Salmonella Enteritidis, all responsible for 3 foodborne illnesses.

- Another significant advantage: the process is non-toxic

- The process of cleanliness by spraying dry ice particles makes it possible to carry out many applications: degrease, strip the rust flower, remove graffiti, sticker … Cleaning car engines or rims In addition, cryogenics can limit production stoppage: production lines are cleaned up to 8 times faster than traditional methods.

- Thanks to the onboard pressure regulator, you can now deburr plastic parts. The process is fast and efficient and complies with respect for the environment with the use of an electric compressor.

- You can also use the services of a cleaning company by clicking on the Directory link (Menu) and then entering your address in the search bar: for the cleaning of electrical cabinets, plastics or rubber molds or for the treatment or removal of graffiti… and of course for fire restoration!

Address

Delta Broadcast

Head office

Rue Du Bonnard

38290 Frontonas (France)

SHOWROOM ADDRESS

Showroom

Rue Des Muguets

Parking Carrefour Market

38070 Saint Quentin Fallavier

WEB ACCOMMODATION

Ovh

2 Kellermann Street

BP 80157

CEDEX ROUBAIX 1

Phone : +33 8 99 70 17 61

CONTACT

Tel: +33 981 37 76 93

Website: www.cryoblaster.com

Email:

contact [at] cryoblaster.fr