HOME > DRY ICE BLASTING > BENEFITS

Benefits OF DRY ICE blasting

Dry ice blasting is an industrial cleaning technique free of all chemicals, water, and abrasive products such as those used in sand blasting.

This process uses dry ice as a cleansing agent: it is carbon dioxide (CO2) in solid form, with certain characteristics that, in terms of benefits, make the dry ice blasting method of cleanliness better than all others. Find the benefits of dry ice blasting below.

How does cryogenic cleaning work in a nutshell?

The dry ice blasting technique relies on the projection of dry ice pellets onto the surfaces to be cleaned.

The projection vector is compressed air, which is either under industrial pressure or from a thermal compressor. This will be done by using an ATX blaster, equipped with a blasting hose, a gun, and a supersonic spray nozzle.

Loaded with kinetic energy, dry ice pellets (or dry ice) impact pollution or contaminants, causing surface pollution to be detached by:

- mechanical shock (the pellets carry kinetic energy),

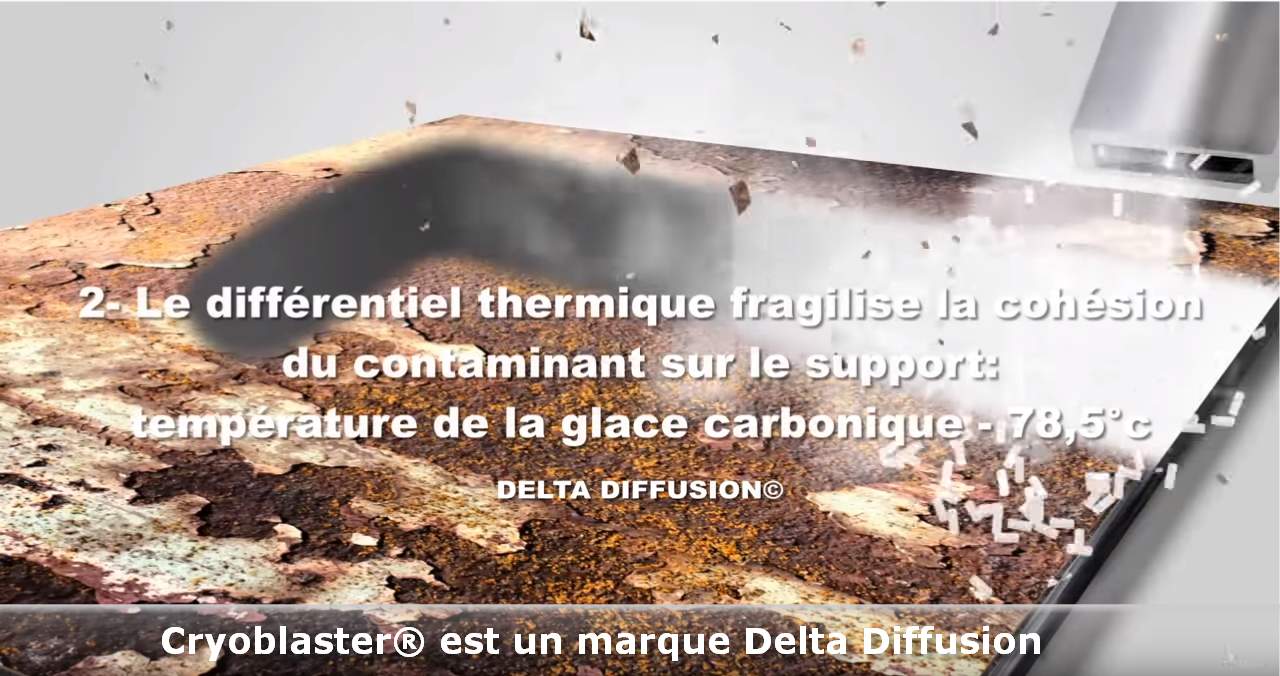

- thermal shock (or thermal differential) and…,

- sublimation, which is the transition of dry ice from solid to gaseous state in a ratio of 1 to 700. The dirt is then instantly removed from the surface.

For more information on the dry ice cleaning process, click at the bottom of the page on the link: “Dry ice blasting how does it work ?”

More details on the dry ice cleaning technique are on the page base. Click on the link: Dry ice blasting: how does it work?

Let’s compare cleanliness techniques

Traditional industrial cleaning usually involves dismantling the machines to be cleaned. The cleaning of the parts is then carried out in a dedicated area. Traditional methods also have limitations when machines cannot be moved, or when other cleanup techniques would result in extended cleaning and downtime. As noted above, dry ice cleaning has many advantages over other traditional cleaning methods.

Let’s see which ones…

Dry ice blasting: Dry cleaning

Cleaning techniques that use water for cleanliness, such as high-pressure cleaning, generate moisture in the treated area and require time to dry the parts, so they can be reinstalled.

Water cleaning can cause rust, which damages metal parts and promotes the growth of bacteria such as Salmonella, Listeria, and Escherichia coli.

Because dry ice is solid carbon dioxide, the cryogenic cleaning process is a dry and “disinfecting” cleaning technique that inhibits the growth of the bacteria mentioned above due to its extreme temperature. The temperature of dry ice is -80 degrees Celsius.

That’s why many agri-food and pharmaceutical companies today are equipping themselves with dry ice cleaning machines like the ATX25 or ATX Nano, thus eliminating cross-contamination.

A quick reminder:

The medium used is dry ice, or so-called “dry ice,” which goes from solid to gaseous without an intermediate liquid phase.

Dry ice blasting prevents the proliferation of the bacteria mentioned above, mould, or the appearance of rust on metal surfaces.

Dry ice cleaning operation on an escalator. High-pressure cleaning is impossible in this type of configuration…

Chemical-free Cleaning

Cleaning methods that use chemicals can not only damage parts of the machines treated, but can also pose a serious danger to operators and the environment.

In addition, the use of large quantities of chemicals involves waste reprocessing.

Free of any chemicals, the advantages of cryogenic cleaning are:

-

- it poses no danger to users,

- it leaves no type of residue, thus saving the additional cost of secondary waste disposal, and above all,

- it is by far the most environmentally friendly technique: dry ice sublimates on contact with the surface to be cleaned, returning to gaseous CO2 form,

- it does not require chemicals that impact the ozone layer during its production,

- it does not generate unpleasant odors, unlike the use of solvents…

With the projection of dry ice, even heavily clogged surfaces do not require chemicals such as solvents…

Increased Productivity and Profitability!

Traditional cleaning methods typically involve stopping machines or manufacturing processes, disassembling the parts, allowing them to dry, and then reassembling the parts after cleaning.

It goes without saying that traditional cleaning techniques are time-consuming…

Ideally, the re-cleaning phase should be quick, generate minimal residue, and require little to no disassembly…

Well, the time and money savings with dry ice cleaning are significant!

Indeed, the advantage of dry ice cleaning is that it is not necessary to disassemble and reassemble. Parts can be cleaned on-site without additional downtime.

Example: Agri-food

Cleaning 2 conveyor chains of 750 linear meters each.

The traditional technique involves disassembling over 2 days, sending the 2 chains to another site for cleaning and cleaning for 3 days, then returning to the customer’s site and reassembling over 2 days. That is a total production stoppage of 7 days, at a cleaning cost of 30,000 euros, not counting the costs associated with production shutdowns.

Dry ice cleaning, with 2x Cryoblaster ATX80 and ATX25 cleaning units, allows the chains to be degreased, on-site, without disassembly in just 2 and a half days, or 4 and a half days less production stoppage !

Dry ice cleaning is 2 to 8 times faster than traditional methods. So, the process is very fast.

Dry ice cleaning of agri-food chains: 2 1/2 days versus 7 days with

the traditional method…

A quick reminder:

Dry ice cleaning is a dry process, there’s no need to wipe or dry the treated surfaces: save time! Thanks to various types of nozzles, cleaning is much more thorough and allows cleaning in every nook and cranny. As a result, the equipment works more efficiently and potential leaks (e.g., hydraulics) are revealed.

A Technique That Ensures the Longevity of Production Tools

Because dry ice is dry, it does not promote the corrosion of metal surfaces. This technique can therefore be used to clean electrical equipment under voltage: as these are not likely to cause electrocution by direct contact.

Important: Cleaning electrical cabinets under voltage requires technical clearance. Make sure the operator has taken this kind of training. Otherwise, if an accident happens, you may be held liable. Cleaning off-voltage and recorded electrical cabinets require H0B0 clearance (France).

In addition, the hardness of dry ice is comparable to that of chalk and therefore does not scratch the treated parts, unlike some tools such as spatulas, scrapers, or scraping sponges: industrial cleaning with dry ice increases the life of the work tool by minimizing wear and keeping the machines in good working condition. The process is non-abrasive.

Among the many advantages of dry ice cleaning, the gentleness of the treatment is much less dense than sand and above all, sublimates (transition from solid to gaseous state, in a ratio of 1 to 400) upon contact with the surface to be treated.

Important: To ensure the feasibility of a cryogenic cleaning project on a surface you are not used to treating (wood, plastic, etc.), always start at low pressure, and adapt the ice granulometry and the type of nozzle according to the contaminant, the support, and the desired result.

Some tools or accessories can damage treated surfaces…

The hardness of the dry ice is only 2 mohs, which is the hardness of the chalk.

Dry ice blasting treatment is not abrasive.

In summary, the benefits of dry ice blasting are:

- A safe industrial cleaning process for operators, machines, and the environment: no chemicals (no solvents, no detergent, no abrasives).

- A technique that does not contribute to the increase in greenhouse gases (as long as compressed air is electrically powered). The carbon dioxide in the ice is made with recycled CO2, which is ultimately given a second useful life.

- A dry, non-abrasive, non-conductive cleaning technique using non-flammable media, 2 to 8 times faster than traditional techniques, due, among other things, to the fact that it does not always require disassembly to clean the surfaces.

Address

Delta Diffusion

Head office

Rue Du Bonnard

38290 Frontonas (France)

SHOWROOM ADDRESS

Showroom

Rue Des Muguets

Parking Carrefour Market

Mall

38070 Saint Quentin Fallavier

WEB HOSTING

Ovh

2 Rue Kellermann

BP 80157

CEDEX ROUBAIX 1

Phone :+ 33 8 99 70 17 61

CONTACT

Tel: +33 9 81 37 76 93

Website: www.cryoblaster.com

Email:

contact [arobase] cryoblaster.fr