Cryogenic cleaning: soot in EDF room…

Following a fire, the problems continue, even after the flames are extinguished. Indeed, after assessing the damage, you are faced with the heavy task of putting everything in order. Your priority: quickly return to the original state of your home or premises. Dry ice blasting is then the ideal solution. Discover, in this article, the benefits of dry ice cleaning of fire damage.

Cryogenic cleaning: an innovative and fast stripping process

Dry ice blasting consists of projecting a mixture of compressed air and dry ice at low pressure onto the surfaces to be sanitized.

Since the process does not use chemical detergents or solvents, it allows different types of residues to be treated without producing secondary waste. Moreover, it is a method at the same time, non-abrasive and ecological, increasingly appreciated.

Dry ice blasting quickly and efficiently removes all traces of dirt after a fire: soot, charring, smoke and odours.

Unlike traditional cleaning methods, treatment with dry ice can reduce the duration of the work by half. This is also the reason why the cost of the process can be half as expensive for deeper cleaning.

In reality, it is the technique to be preferred to restore a room or a dwelling at a lower cost. Among the benefits of dry ice cleaning of fire damage, this process can be carried out safely on sensitive installations.

Examples: electrical appliances or plumbing.

Dry ice cleaning: a perfectly adapted method for disaster cleaning

Typically, the persistent smell of smoke and burning is one of the most challenging problems to deal with after a fire. Fortunately, dry ice cleaning will solve this issue in just 24 hours, thanks to dry ice cleaning. In addition, this technique is also ideal for treating hard-to-reach places, often neglected as part of deep cleaning.

Of course, thanks to its efficiency and treatment process, dry ice blasting also makes it possible to remove soot, smoke and any other contaminants without constraints. In some cases, this technique can even be used to remove mold that has increased on the walls.

Dry ice blasting is the most environmentally friendly intervention among all the surface treatment processes currently available. Discover by clicking on the following link the Cryoblaster dry ice blasters.

Even if its realization seems simple, it is however necessary to entrust the work to a professional to benefit from a quality cleaning and in accordance with the rules of the art.

The advantages of the cryogenic solution when restoring a place after a disaster caused by fire are numerous:

- Reduced treatment time

- Non-abrasive cleaning without secondary waste

- No treatment or cleaning to consider after the operation

- Effective removal of recalcitrant odors

- Reduced labour costs

- No reprocessing of secondary waste

- No need for drying : the treatment is dry

- Perfect for hard-to-reach areas

Cryogenic cleaning operation on weather station following a fire…

Recent posts

More posts...

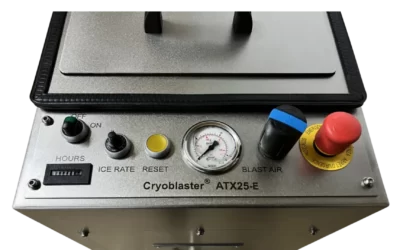

ATX25-E V1 : new dry ice cleaner

Don't miss out on the revolutionary cleaning solution for your industry! Discover the incredible benefits and unmatched efficiency of our ATX25-E V1 dry ice cleaner by visiting this link (in blue).

Advantages of dry ice cleaning on a fire disaster.

01 February 2022

Discover in this article all the benefits of dry ice cleaning on fire damage

Portable dry ice blaster CB02

20 January 2022

The small new dry ice blaster CB02 is soon here. Click on the blue link for more information.